Bio-Normalizer | Carica Papaya | Fermented Food | Sun-O International Co., Ltd.

Factory tour

The domestic cutting edge industrial park in the Philippines, there is a primary manufacturing plant of Bio-Normalizer.

The Philippine factory of Bio-Normalizer is in the First Philippines Industrial Park of Santo Tomas City,Batangas, on the foot of the dormant volcano Mt. Makiling , 52 km. from the center of Manila( appoximately 1 hr. by car). It is a developed industrial park through the joint development of the local financial clique and Sumitomo Company,wherein 59 companies has moved in (29 Japanese-affiliated companies), Honda Technical Institute Industry Co.,Ltd., Ibiden Co., Ltd.,Sumitomo Heavy Machine Industries Co.,Ltd.,Philip Morris, etc. It is an area accumulated with factories, with approximately 16,000 workers which will support the Philippine economy.

<画像>

There is a dedicated passage for inspection tours of the factory.

In the new factory completed constructed in April, 2010, a fully equipped room exclusively for the control of continuous humidity temperature for the fulfillment of the fermentation of green papaya.Inspection and other delicate operation is not trusted to the machine, it is carefully done one by one by man, and the staffs with qualification performs a precise inspection in the laboratory that is fully equipped with examination instrument for the consistency of quality control.

And in the new factory an exclusive passage was prepared for visitors who comes to observe the factory and every manufacturing process. And even the regular dealers in Japan is taking the initiative to visit the factory in the Philppines and observe the the system on the method of consistent quality control of Bio-Normlizer and training is also conducted.

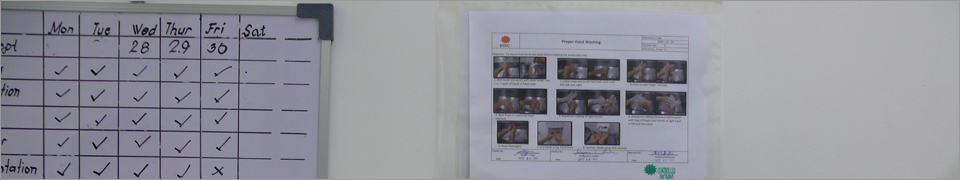

Training scene in the factory

A passage exclusively for visitors

Introducing some of the touring course

Sanitation room

Wearing clean uniforms, of which the hems of cuff,coat and pants is airtight to avoid mixing of falling hair and others to the products,

<Sanitation check >

Papaya processing room

The underground natural water is used for washing. The surfaces of the green papaya are carefully hand-washed by one by one.After washing with water the surface of the green papaya is rinse with a pure water.And the washed green papaya is being cut as it is, with the pit, skin and seed.Utilizing the maximum active ingredients of the green papaya in fermentation, maintaining the freshness it is quickly processed in a short time.

<Cleaning >

<Cut >

Drying room

The condition is checked everyday by a skilled worker and manually mix and meticulously controls the tmperature and humidity level. It takes a long period to deliberately ferment.After the fermentation period the raw material is slowly dried in a low temperature.

<Maturation >

<Drying >

Inspection room

Implementation of visual inspection to all finished products on all lots to make sure that no foreign object is mixed.

<Inspection>

Laboratory room

Inspection for the presense of saprophytic bacteria.

Then, the inspection of common bacteria and a coliform bacillus inspection successively.

Also, a high criterion of more than 90% is provided for the measurement of the eliminated ratio of reactive oxygen of the food through ESR (electronic resonance spin device) which measure the eliminated ratio of reactive oxygen.

<Saprophytic bacteria examination >

<Laboratory dish >

<Quality control>

Compression room

A very difficult work is perform to mold form only by pressure.

<Compression molding >

<To confirm if compression is made >